As consumer preferences worldwide shift towards beverages that prioritize both personal well-being and environmental sustainability, the beverage industry faces the challenge of meeting high-volume demands for functional-healthy, non-alcoholic, and super-premium alcoholic drinks. This trend extends beyond home consumption to the vast HORECA (hotel/restaurant/cafe) channel globally.

Benefits

Products used in the beverage industry

To keep up with the rapid movement of products on a global scale, the industry has embraced high levels of automation, particularly in the western EU, most of the U.S., and Japan, with other regions following suit.

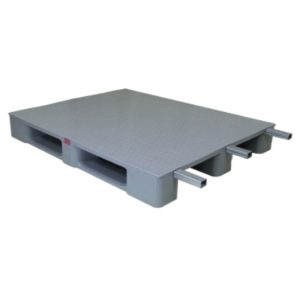

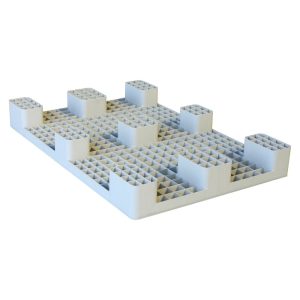

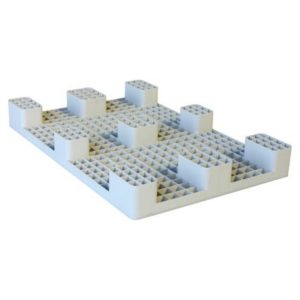

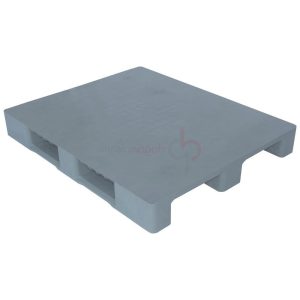

Plastic pallets have emerged as a preferred choice for load carriers due to their advantages. Doğan Plastik’s plastic pallets, designed for the beverage industry, boast a lifespan four times longer than heavy-duty wooden pallets. Through our circularity initiatives, which involve repairing, servicing, and recycling broken pallets, we further extend the lifespan of damaged materials.

Efficient global beverage distribution often encounters less-than-ideal storage conditions, necessitating highly diversified systems. Doğan Plastik has been meeting these demands for decades with products like MP and MW series .

Worker safety is a paramount concern throughout the industry, and our choice of plastic over wood aligns with this priority. Doğan Plastik offers ergonomically designed pallets featuring anti-slip systems, ensuring both workforce well-being and the security of the products being handled. Moreover, our use of post-consumer and post-industrial materials not only benefits the environment but also contributes to a positive bottom line.

Studies show that 88% of consumers exhibit greater loyalty to companies that champion sustainability. Doğan Plastik’s recyclable, waste-eliminating smart pallets offer a customizable and reliable solution for the diverse needs of the beverage industry, aligning with both consumer preferences and industry priorities.